Unlocking the Potential of **China Prototypes** in Metal Fabrication

Introduction to China Prototypes

The rapid evolution of manufacturing and prototyping has paved the way for innovative solutions that streamline production processes. China prototypes refer to prototype products and services from China's leading manufacturers, increasingly becoming the backbone of numerous industries globally. With Deep Mould, a premier name in Metal Fabricators, understanding the realm of chinese prototypes can dramatically enhance your business efficiency and output quality.

Understanding Metal Fabrication and its Importance

Metal fabrication is the process of transforming raw metal into finished products. This includes a wide array of services such as cutting, bending, welding, and assembling. For businesses engaged in manufacturing, the importance of high-quality metal fabrication cannot be overstated. Reliable metal fabrication allows companies to:

- Minimize production costs: Efficient processes lead to decreased waste and minimized resource use.

- Enhance product quality: Precision in fabrication ensures that final products meet stringent quality standards.

- Shorten time-to-market: Rapid prototyping allows for quicker product development cycles.

- Facilitate custom solutions: Tailored prototypes meet specific client demands effectively.

The Role of China Prototypes in Metal Fabrication

When it comes to metal fabrication, china prototypes are increasingly recognized for their efficiency, cost-effectiveness, and variety. Here are key factors contributing to their rising prominence:

1. Cost-Effectiveness

One of the most significant advantages of sourcing prototypes from China is the cost savings. Low labor costs, abundant raw materials, and a highly developed supply chain all contribute to reduced production expenses.

2. Advanced Technology

Chinese manufacturers are often at the forefront of adopting the latest technologies in metal fabrication. The integration of CNC machining, laser cutting, and automated assembly lines allows for precision and quality that meets international standards.

3. Versatile Material Options

China provides a multitude of material choices for prototyping. Whether you need steel, aluminum, or specialized alloys, you can find a factory that can produce prototypes that meet your specifications:

- Aluminum: Lightweight with excellent corrosion resistance.

- Stainless Steel: Durable and ideal for high-strength applications.

- Specialty Alloys: Tailored to meet particular requirements for demanding environments.

Key Processes Involved in Developing China Prototypes

The process of creating prototypes in China involves several key stages, which we will delve into:

1. Conceptualization and Design

The first step in prototyping is the development of a concept that meets the functional requirements of the end product. Using CAD (Computer-Aided Design) software, designs are accurately created and modified based on client feedback.

2. Rapid Prototyping Techniques

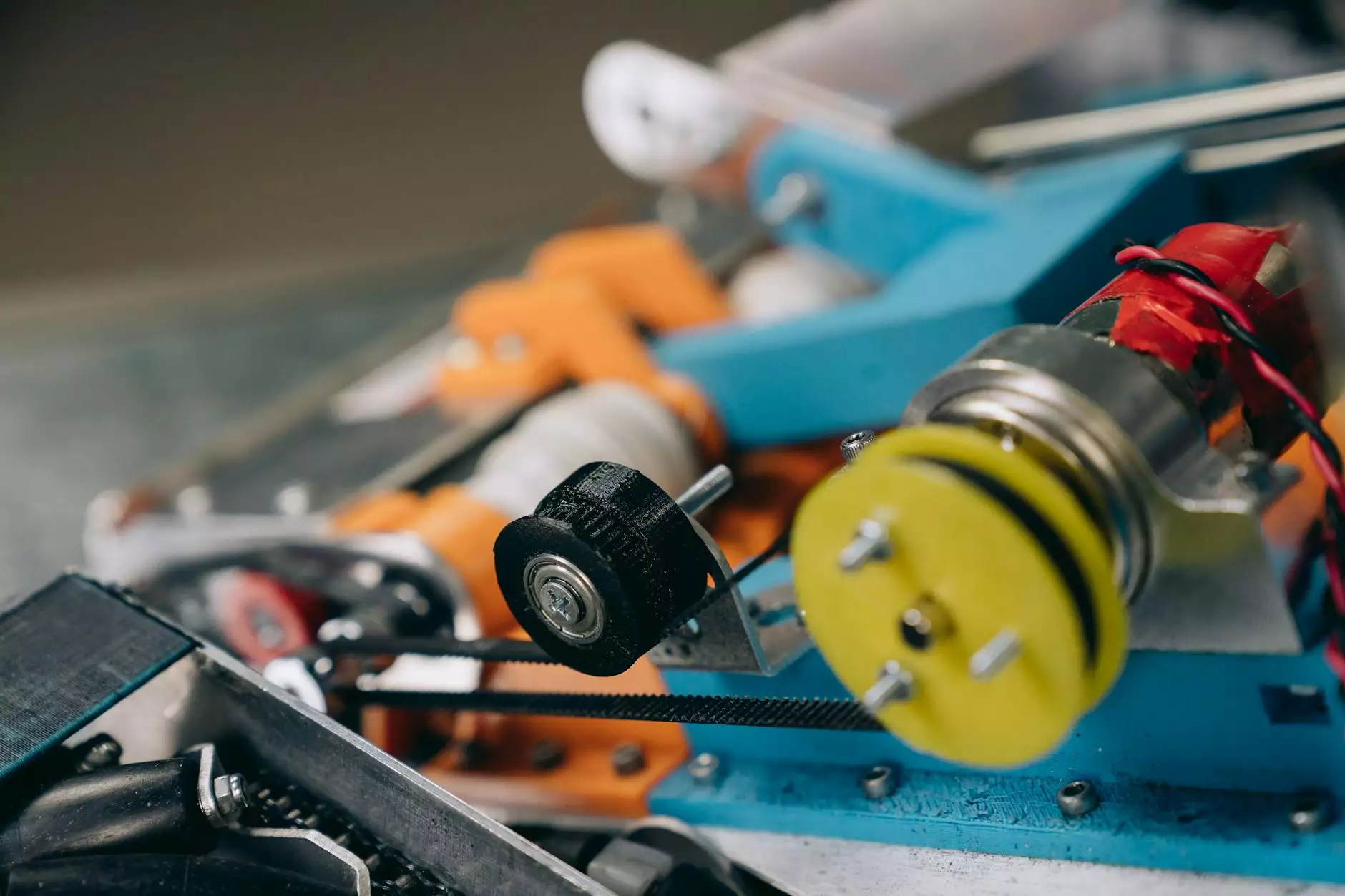

Among the china prototypes techniques, rapid prototyping is prominent. This includes:

- 3D Printing: Ideal for complex geometries and quick design iterations.

- CNC Machining: Suitable for creating high-precision metal components.

- Injection Molding: Perfect for producing test runs of plastic and metal parts.

3. Testing and Validation

Once prototypes are fabricated, they undergo rigorous testing to ensure performance and durability. This feedback loop is crucial, enabling manufacturers to refine designs before full-scale production.

Advantages of Choosing Deep Mould for Your Prototype Needs

By partnering with Deep Mould, your business can leverage several advantages:

1. Expertise in Metal Fabricators

With years of experience, Deep Mould specializes in metal fabricators, offering unparalleled knowledge and craftsmanship in creating state-of-the-art prototypes.

2. Customized Solutions

Each project is unique, which is why we offer tailored solutions designed specifically to meet your project’s specifications, ensuring that every prototype is a perfect fit for your needs.

3. Commitment to Quality

Quality assurance is at the heart of everything we do at Deep Mould. Every prototype undergoes rigorous inspection processes to guarantee that it meets the highest quality standards.

4. End-to-End Service

From initial consultation to final delivery, we provide a full suite of services, ensuring that clients receive exceptional support at every stage of the prototyping process.

Innovation and Future Trends in China Prototypes

As industries evolve, so do the technologies and efficiencies of prototyping:

1. Sustainability Practices

With increasing awareness of environmental issues, many companies are shifting toward sustainable practices. China prototypes are leading the charge by adopting eco-friendly materials and energy-efficient processes.

2. Integration of AI and Automation

The future of prototyping lies heavily in automation and AI. These technologies help in minimizing errors during the manufacturing process, increasing speed, and enhancing overall productivity.

3. Enhanced Customization

Customers are looking for more personalized products. The demand for china prototypes that offer customization options will continue to grow, pushing manufacturers to innovate in their service offerings.

Conclusion: The Advantage of China Prototypes for Your Business

By collaborating with Deep Mould, your company can take full advantage of what china prototypes have to offer. From increased efficiency and reduced costs to improved product quality and faster time-to-market, the benefits are substantial. As industries continue to evolve, the adoption of innovative prototyping techniques will be critical for remaining competitive in a global market.

Investing in china prototypes is not merely about cost savings; it's about enhancing your overall production capabilities and ensuring that your business can meet the demands of the future. Partner with the best in the field and witness the transformation in your prototyping processes today!